|

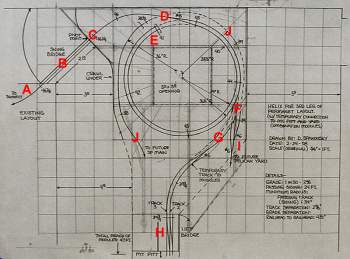

Dave Spakousky drew up a plan for

the

helix and Larry Tuttle developed a framing plan and materials

list.

Track on the permanent layout had already been laid to A. A swing bridge will be

built at B connecting to

the helix section at C.

The Keno siding would begin at D,

winding downward and entering a "tunnel" at E. A road at F will conceal the two tracks as

they emerge at G.

Temporary trackage will be laid to the modular lift bridge at H. Eventually, permanent

track will be laid at I

and continue down to connect to the rest of the Klamath Falls

"leg." A continuous run loop will diverge from I to J to allow continuous running

through the P&E, SP and BN yards. Because part of the loop

will be buried in the helix, it is necessary to build it now; it may

connect to the lift bridge at H

to provide staging for BN and/or SP trains.

Note the red letters on the plan correspond to similar red letters in

the photos below.

|

|

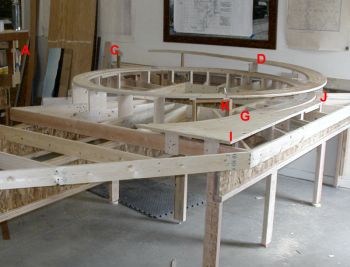

Dave, Larry and

Ed Kleinman spent just over a morning putting together the BCI girders,

and 2

x 4 legs. After five years of working on a layout built with this

type of construction we are convinced that it is superior and VERY

sturdy. It also goes together quickly.

|

|

Initially Larry wanted to

just fasten the helix to the east wall with a 2 x 4 screwed into

studs. However, Dave pointed out that the floor to our clubhouse

as been known to shift up and down and that we might want to allow for

some up and down motion. Larry came up with "truss clips" to

secure the right-most BCI to the wall while allowing vertical

movement.

|

|

Day Two saw Dave, Ed and

Larry complete the 1 x 4 joist system. The main line leaves the

existing layout at A and

crosses the swing bridge to B.

The temporary lift bridge to the modules will rest on the BCI and

plywood structure at H

|

|

The fan of radial joists is

sort of artsy looking. It will provide ample support for the

helix tracks. With three people working, this part went

fast. Lengths were marked ot each joist by holding it in place

(no measuring!) and at the same time taking the angle with a sliding

T-bevel. Then the chop saw was set to the angle and two cuts made

on the lines. Drywall screws hold everything together. The

trick with screws is to pre drill/countersink each hole. 1 x 4's

can then be "toe screwed" into BCI's and other members at up to a

30º angle to the 1 x 4.

|

|

After a couple of very

productive days, we took a minute to stage the "First Train to

Nowhere". It's coming off the permanent layout at A, over bridge site, B and onto the helix benchwork

at C.

|

|

Day Three began as we spread

out two sheets of 3/4" plywood and Dave laid out the helix

curves.

|

|

This

picture begs the "Caption This" title.

Spreading mayo on a roadbed sandwich?

Actually, Dave and Ed are re-gluing a "blow" or section of plywood

which had delaminated. While it's kind of a nuisance, the plywood

was donated and most of it is in good condition. An hour with

clamps and this piece sub-roadbed will be as strong as any other.

|

|

A morning of drawing and

sawing (and gluing) and the sub-roadbed was ready to be installed on

risers.

We also moved Mt. Pitt (foreground) to its new location and clamped the

lift bridge (brown contraption) in place.

|

|

By the end of Day Four, the

sub-roadbed for the lower level of the helix had been permanently

anchored on risers. The plywood from K to D was just laid in place for

this picture since track needed to be laid on the lower level

first. There was just a little more work to this than first meets

the eye. Our standards for layout construction require

super-elevation on main line curves. We also want the main

line elevated slightly (~1/4") above secondary trackage.

While the inside passing track was simply screwed to risers, the main

line required shims to raise and super-elevate. A little more

work, but a most dramatic effect when complete.

|

|

Road Master E. Don got right

to work laying the track for the first level. He wanted to stay

ahead of the sub-roadbed going in for the second level.

|

|

Next was the support system

for the second level. Larry insisted that building the second

level directly over the first could be done...easily and

sturdily. He almost wished he hadn't said that until he came up

with inverted 3/4" x 1/2" extruded aluminum channel supported by 3/4" x

3/4" wood "cube". It kind of looks like over-sized supports for

catenary. The sub-roadbed was drilled and screwed through

the aluminum (with shims for the main line) and made for a very sturdy

helix structure.

|

|

The ascending main line and siding stacked neatly over the lower level tracks.

(Ed. note: In the three years the helix has been in use, this construction method has proven very sturdy and relaible with no adjusments needed in the track support system.)

|

|

With the bulk of the helix track laid, attention turned to getting the main line across the aisle and connected with the rest of the layout. Several options were considered including a fixed duck-under (which was immediately nixed!), a lift-out section (also nixed) and a swing-away bridge. The swing-away bridge would be the choice IF it could be built sturdy enough and made to operate reliably. |

|

Larry fabricated the roadbed and ends of the bridge out of 2 1/2 x 3/4" material and braced it with two diagonals. Then, he cut 3/16" Masonite into a pair of arched bridge sides and glued and pinned them in place. The resulting structure is very rigid. A pair of 3 1/2" butt hinges hold the bridge securely to the benchwork while allowing it to swing out of the way for people. DCC bus wires were soldered to each hinge half and electrically conductive grease lubricated the hinges. This eliminated the need for any loose wires attached to the bridge. A roller catch was drilled up into the bottom of the other end of the bridge and lodges into a receiver plate mounted on a little shelf on the far wall. Not shown are two micro-switches, one on each side, which interrupt track current for four feet or more in each direction when the bridge is open. |

|

A pop-up is built in the middle of the helix and basic land forms are developed. Then, after a trip to Klamath County and a hike on an old Weyerhaeuser grade, a spectacular scene takes shape. |